Made in Space Inc. is known as the company behind the 3D printers on board the International Space Station. Astronauts have used the startup’s AMF, or Additive Manufacturing Facility on the ISS, to churn out everything from finger splints to tools, sculptures and even other printer parts.

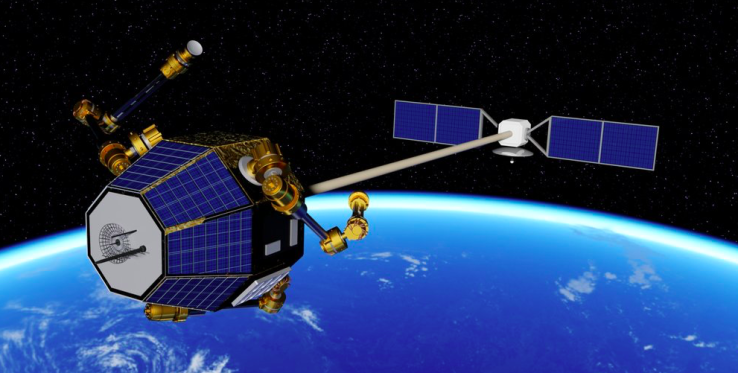

Now, the company is revealing a video rendering of its larger Archinaut system, a factory in the sky operated by autonomous robots. The Archinaut can produce and assemble large equipment such as satellites or even entire spacecraft while in orbit.

According to Made in Space CEO and President Andrew Rush, “It’s our ambition to develop the manufacturing technologies that will usher in the era of true commercial space utilization.” Literally, he is hoping to enable colonization of other planets, with millions of people living and working in beautiful, microgravity environments.

The company believes, he said, “Manufacturing things in space lets us unlock possibilities you can’t when you have to design things to survive launch.” During launch, tremendous forces push down on any spacecraft and the people within, obviously. Rush added, “Any time you can pack more efficiently, and save mass, it helps make new missions possible or current missions more cost-effective.”

Some of the biggest scientific and engineering challenges the company faced, when developing the Archinaut, were around material choices and hardware. The company had to determine which materials could be used for its own systems’ parts, as well as to be extruded by the system, and assembled and used in space.

“You have to figure…